Metallization of electric grade base film

At STANDARD CAPACITORS PVT. LTD. we metalize electric grade capacitor film on CAP-M-650 and CAP-M-950, LEYBOLD OPTICS GMBH make.

Silent Features

CAP-M – High flexible system for the mass production of metalized film for capacitors Designed for the future and designed to perform the demanding requirements of an unlimited range of metalized films for capacitors. From standard- to high-end applications, from thick to thin films, from plain to segmented designs, from thick to thin layers, from pure layers to layer-stacks every conceivable combination can be realized in one system.

Slitting of metallized electric grade film

At STANDARD CAPACITORS PVT. LTD. we slit metalized electric grade capacitor film on CAP Microslit of KAMPF GMBH make and VACOTEC Korean make.

Silent Features

KAMPH MICRO SLITTING MACHINE, GERMANY- High speed wave cutting can cut precisely very narrow width ultra thin film.

VACOTEC SLITTING MACHINE,KOREA- Managing a slitting capacity of 1000x4 kgs. per day with precise slitting of heavy edges and free margins.

Specialized wavecut slitting option with minimum widths upto 4.5mm and free margin of 0.5mm and maximum width upto 150mm.

Winding of electric grade capacitor metallized film

At STANDARD CAPACITORS PVT. LTD. we wind metalized electric grade capacitor film on Metronics and Twincap of METAR SA make.

Silent Features

METRONICS-Dual concentric winding system and Triple concentric winding system. Edge guiding system for metalized film. Independent Film tension. Variable film tension during main winding.

TWINCAP- Very precise tension control. Thermo-sealing at the beginning of the winding. Cover film insertion device. Burn off of the two metalized films.

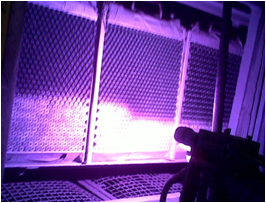

Spray process of capacitor winding elements

At STANDARD CAPACITOR PVT. LTD. we have developed a consistent spray system with temperature control gun. Zinc is sprayed evenly on both the sides of each winding.

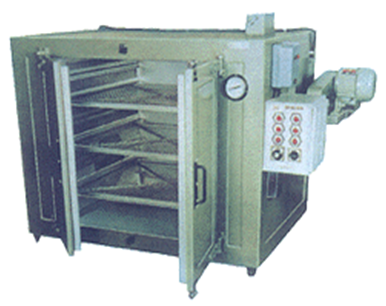

Tempering of capacitor elements

At STANDARD CAPACITOR PVT. LTD. we use industrial oven for tempering of windings at 85⁰C for 6 hours.

Clearing of capacitor elements

The machine facilitates automatic loading of elements up to 25 mm diameter and Manual Loading up to 40 mm diameter. Initial AC Short Clearing, DC Short Clearing, DC Test, AC High Voltage Test, Discharge through resistor, Direct Short, Capacitance Value and Tan D measurement.

Soldering and weilding of capacitor elements and wire/terminals

At STANDARD CAPACITORS PVT. LTD. we use manual soldering gun for soldering of PVC cables to the winding of the capacitors.

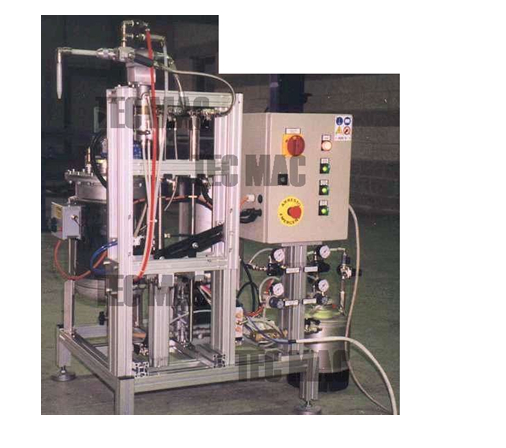

Pu filling and encapsulation of capacitors

At STANDARD CAPACITOR PVT. LTD. we use automatic dispensing machine for PU filling from P&R Technologies, Korea make. Combination of epoxy and hardener is dispensed from one nossel.

Capacitor final testing machine

At STANDARD CAPACITOR PVT. LTD. test capacitors on ACT 2001 of Wuxi Lead, CN make. This machine is designed for final electric capability testing of metalized AC capacitors. It is applied for AC capacitors wrapped by plastic or metal, exit of which is lead wire or metal inserted terminators. It has 2 fasten terminals. Capacitors with either round or square shell can be tested.

Printing of capacitors

High performance printing

Up to 4 lines of printing for “best before” dates, logos, alphanumeric text, 1D and 2D barcodes.

Print speeds of up to 6.6 m/s.

Font heights of up to 32 dots.

Optional ultrarapid mode for high-speed printing.

Broad range of specialty inks, including returnable glass ink for washable marking.